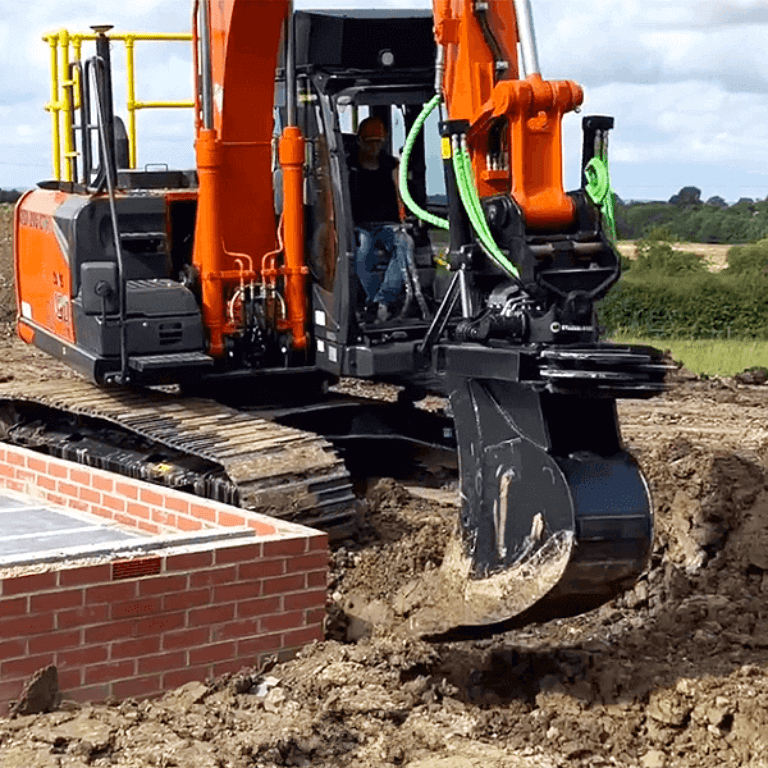

When it comes to maximizing the productivity of your excavator, every detail matters. Whether you’re in construction, forestry, or utility work, the right equipment can mean the difference between completing a job ahead of schedule or struggling to meet deadlines. Steelwrist Tiltrotators stand out as the industry leader, offering unmatched efficiency and durability compared to competitors’ tiltrotators and traditional excavator couplers.

Let’s dig into why Steelwrist is the go-to choice for professionals who demand more from their equipment.

Efficiency: Do More, Faster

Time is money in the excavation world, and Steelwrist Tiltrotators are engineered to save you both.

1. Increased Versatility

Steelwrist’s 360° continuous rotation and ±45° tilt capabilities allow operators to work at any angle, eliminating the need to reposition the machine repeatedly. This adaptability is a game-changer when working in tight spaces or tackling complex projects. Competitor models may offer similar flexibility, but Steelwrist’s smooth and precise controls ensure every movement counts.

2. Seamless Integration with Attachments

Steelwrist’s quick coupler system is designed to integrate effortlessly with a wide range of attachments. Switching tools is faster than ever, keeping downtime to an absolute minimum. Traditional couplers? They just can’t compete—every manual attachment change costs valuable minutes, if not hours.

3. Fuel Efficiency

Thanks to the reduced need for repositioning and smarter movements, Steelwrist Tiltrotators help operators save on fuel costs. Competitor models often lack the same level of precision, leading to more wasted energy over time.

Durability: Built to Last in the Toughest Conditions

Steelwrist Tiltrotators are built with longevity in mind. Designed for rugged environments, they hold up to the abuse of heavy-duty operations better than the competition.

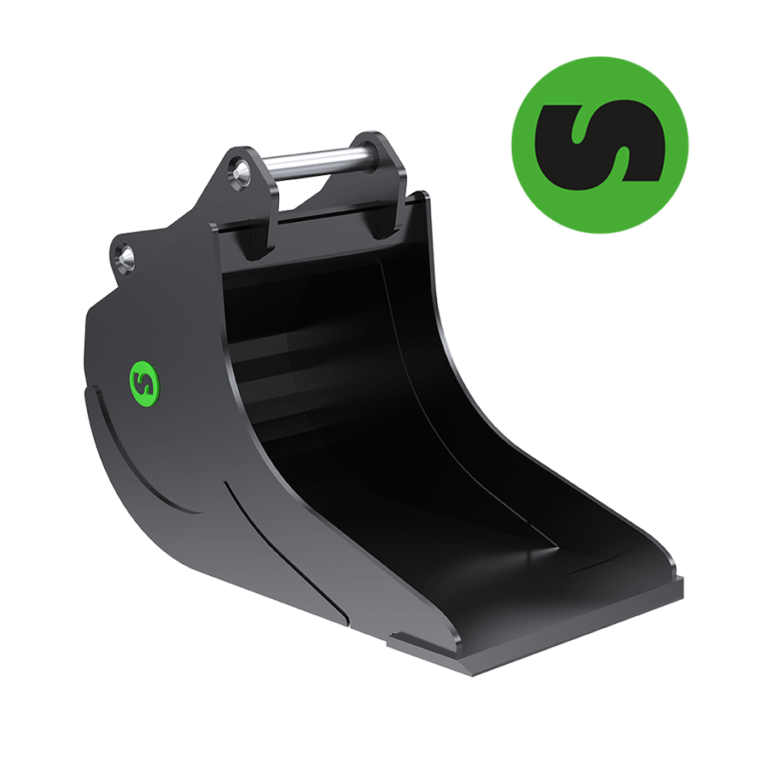

1. High-Strength Steel Construction

Steelwrist’s tiltrotators are crafted from advanced high-strength steel, making them lighter yet stronger than many competitors’ models. This balance reduces wear on your machine while ensuring the tiltrotator can handle whatever the job throws at it.

2. Reinforced Sealing and Protection

Whether you’re working in dusty, wet, or freezing conditions, Steelwrist’s patented sealing technology prevents debris and moisture from compromising performance. Competitor models often falter in extreme conditions, leading to costly repairs.

3. Low Maintenance, High Performance

Steelwrist’s robust design means fewer parts are prone to failure, minimizing maintenance needs. Combined with easy access to service points, you’ll spend less time in the shop and more time on the job site. Traditional couplers and lower-quality tiltrotators frequently require more upkeep, cutting into your profitability.

Why Steelwrist?

Steelwrist doesn’t just make tiltrotators; we redefine what they can do. Our focus on innovation, user-friendly design, and premium materials means that your investment in Steelwrist equipment pays off in both the short and long term.

When stacked against competitors’ tiltrotators or the old-fashioned excavator coupler setup, the choice is clear. Steelwrist Tiltrotators are the ultimate solution for operators who demand efficiency, reliability, and top-tier performance.

Don’t Settle for Less

Why settle for equipment that slows you down or breaks under pressure? Upgrade to Steelwrist Tiltrotators and experience the difference for yourself. With Steelwrist, you’re not just buying a tool—you’re investing in a partner that helps you work smarter, faster, and more profitably.

Let’s get the job done right. Contact us today to see how Steelwrist can transform your excavating operations!